Sinkholes are the lurking underground menace no one wants to think about and definitely don’t want to deal with when they happen. One day everything is fine and suddenly, with no warning, the ground caves in! With spring comes rainy, cold weather—a perfect setup for a sinkhole to form.

The areas in which sinkholes can occur are related to the geologic conditions, so the occurrence is not totally random. A knowledgeable consultant can assist in determining the relative risk of sinkhole development. As the title says, this article provides a short discussion of how to locate and treat sinkholes. Note the word ‘treat’ instead of ‘repair’. As with certain medical conditions, there is no cure for a site in sinkhole terrain-only treatment and application of suitable construction methods to reduce the risk of future sinkhole occurrences.

While the geologic conditions in which sinkholes can occur are known, the actual occurrence of a sinkhole is unpredictable. Subsurface conditions can stay in equilibrium and stable for many years, and suddenly change due to manmade changes such as pumping from wells or changes in surface runoff. Extreme weather variations such as heavy rainfall or drought can cause dropouts to suddenly occur at a site that was previously stable.

What Is a Sinkhole?

A sinkhole is a localized depression in the surface of the ground that was caused by the removal of underlying material. Naturally occurring sinkholes are mainly associated with limestone bedrock because limestone is susceptible to being dissolved by acidic groundwater. Other geologic formations conducive to sinkhole development include marble and dolomite.

Causes of Sinkholes

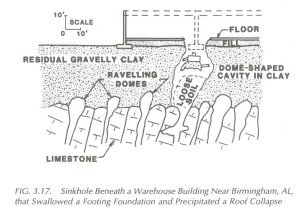

The dissolving (or solutioning) of carbonate bedrock occurs over thousands of years. As the limestone dissolves, soil erodes or ‘ravels’ into the open seams or caverns. The erosion progresses upward toward the surface until a surface collapse occurs. This is shown in the publication “Building on Sinkholes” by G. F. Sowers.

Consider the caves you may have visited. The cave networks are the underlying cause of surface sinkholes. When the roof of the cave collapses, or where cracks and fissures in the rock allow overlying soil to erode into the cave, the void can eventually reach the surface. The cave networks can be very extensive, such as Mammoth Cave in Kentucky, where the network has over 50 kilometers of continuous subterranean passages.

When a large area underlain by such a cave network undergoes collapse and numerous sinkholes occur, the surface topography can change into a series of sinks and large closed depressions, the landscape is known karst topography. The term karst comes from the name of an area adjacent to the Adriatic Sea, where natural sinkholes are numerous. The word ‘karst’ is used to describe areas where sinkholes, either natural or man-induced, occur.

The surface collapse can be slow or sudden, as seen in the Florida event. One of the largest sinkholes in Alabama occurred so suddenly that a local farmer felt his house shudder and then there was a sudden gust of wind within a few seconds. The sinkhole (referred to as the Golly hole) was later found to have a diameter of 300 feet.

Sinkholes may also be caused by manmade factors as well. Broken stormwater pipes are a common cause of soil erosion and subsequent surface dropouts. Underground mining activities have also been related to sinkholes.

Identification of Sinkholes

Now that we’ve discussed the causes, how do you identify areas that are susceptible to sinkholes? Except for manmade features, geology is the major factor in sinkhole development. Most states and some counties have publications that identify sinkhole prone areas. Aerial photographs (sometimes incorporating infrared cameras) can be used to locate existing dropouts or other karst features.

After geological research of the site, a geotechnical investigation plan is developed and executed. The investigation may include:

- Soil test borings—Used to determine the consistency of the overburden soils. The soil test borings are usually drilled to auger refusal to check the variability of the bedrock surface. It is common to find soft soil conditions and an erratic rock surface in active sinkhole areas. It’s important to determine the depth of the soft zone of soil above the rock relative to the thickness of undisturbed soil above.

- Rock coring and/or air rotary drilling—This is used to assess the continuity of the rock. Clay filled seams, void spaces, or caverns in the rock increase the risk of future dropouts.

- Geophysical investigations—Geophysical techniques may include electrical resistivity testing, ground penetrating radar, seismic soundings, or micro-gravity surveys. Electrical resistivity is usually used where clay overburden is present. Electrical resistivity imaging (ERI) is a technique used to map resistance to electrical flow in the ground at varying depths and lateral locations. Electrical current is introduced to the earth by two transmitting electrodes. The apparent resistivity of the subsurface is obtained by measuring the drop in potential between two receiving electrodes along the test alignment. The depth of investigation is proportional to the separations between transmitting and receiving electrodes. By varying this separation, as well as the separations between the pairs of transmitting the receiving electrodes, different depths and locations can be sampled to develop profiles of the subsurface apparent resistivity. These results can often distinguish more competent rock with higher resistivity values from water bearing, weathered or fractured rock having higher conductivity and lower resistivity values.

The results of the investigation are analyzed and the risk for future sinkhole development is assessed. Sites are typically assigned low, medium, or high risk depending on the findings of the investigation.

Treatment of Sinkholes

The remediation or treatment options are based on the risk factors assigned to the site, the sensitivity and importance of the structure, and the risk tolerance of the client. There are several viable options to consider for sinkhole risk reduction. Some of the remediation options include:

- Rock-supported foundations—The use of rock supported foundations and a structural slab system is required to essentially avoid the potential complications related to future sinkhole development. Drilled piers, micropiles, or steel piles are considered for this application. However, there are limitations even for these systems and the risks should be evaluated carefully. This approach is not usually practical for most light to moderately loaded structures due to cost.

- Grouting—Several grouting techniques are used for sinkhole remediation. Some of the methods include cap grouting, low-mobility grouting, and dome filling. A typical grouting process is designed to fill the open voids in the soil and improve the consistency of the soil matrix. The grouting program is usually initiated on a 10- to 20-foot grid pattern. Depending on the grout take and pressures in the primary injection points, secondary or tertiary grout holes may be required.

- Surface stabilization layer—The placement of a geogrid reinforcement layer at the subgrade level is sometimes used to reduce the risk of surface dropouts. The geogrid design is based on the ability of the geogrid to span over the certain size dropout. The major consideration with this method is the selection of the ‘design’ dropout opening. The geogrid manufacturer typically assists in the design services.

- Excavation and placement of inverted rock filter—Repair of existing dropouts with excavation/rock replacement is probably the most common sinkhole treatment method. The excavation is extended to competent bedrock and durable rock is used to replace the removed soil. Large rock (rip-rap) is placed in the bottom of the excavation. Progressively smaller rock is used as the excavation is filled. The purpose is to allow flow of groundwater without causing soil erosion.

While sinkholes are and will continue to be a challenge for many project sites, a proper investigation program can provide the necessary insight to anticipate their presence and oftentimes mitigate their effect.